How can American manufacturing attract young workers? Here are some ideas.

How can American manufacturing attract young workers? Here are some ideas.

America needs a new generation of skilled trade workers to maintain its innovation edge. Meet the people shining a spotlight on the advantages and appeal of a career in trade work.

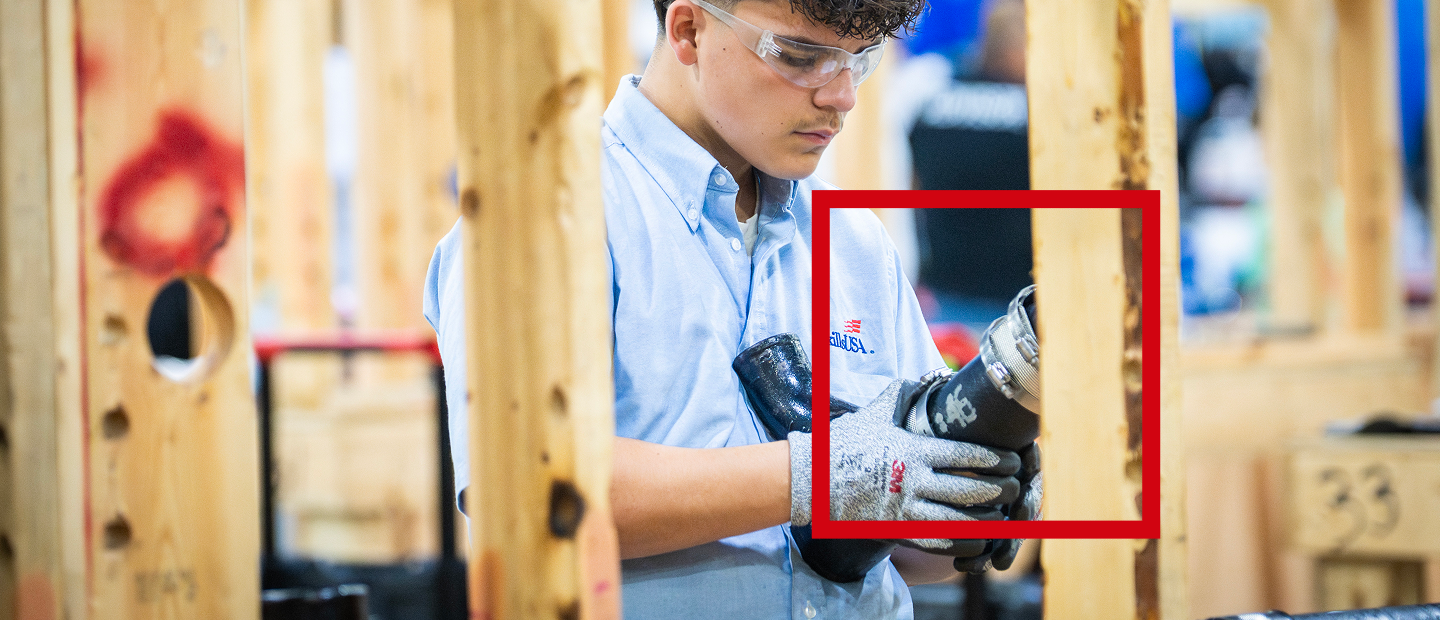

Welding is not typically the type of activity that attracts thousands of middle school, high school and college students. And yet, at this year’s SkillsUSA National Leadership & Skills Conference (NLSC) in Atlanta, Ga., crowds of teenagers and young adults gamely competed in 114 categories including precision machining, aviation maintenance, carpentry and, yes, welding. The conference was attended by 18,000 young people and the competition arena spanned the equivalent of more than 31 football fields.

This singular gathering is hosted by SkillsUSA, the country’s largest workforce development organization for students. The organization describes itself as the bridge between young people and skilled trades, such as masonry, construction, auto repair and manufacturing-specific machining. Today, this mission feels especially pressing. Research estimates that nearly 2.1 million critical American manufacturing jobs will be unfilled by 2030.1 Compounding the crisis, about 40 percent of today’s skilled trade workers will reach retirement age within the next 10 years.2 The impact of this skills gap would be felt nationwide: from lower-quality products (such as unreliable home appliances and motor vehicles) to difficulty accessing essential services (think weeks-long wait times for home repairs).

SkillsUSA sees the solution to the widening skills gap as more nuanced than simply persuading more young people to get trained. The organization aims to inspire and empower young people to want to pursue skilled trade work. “We elevate the skilled trades and really celebrate the opportunities that are available in those careers,” said Chelle Travis, Executive Director of SkillsUSA. “And industry partners help us do that.”

Bailey Barnes, a trade welder, tries her hand at applying 3M Protection Wrap Film in 3M’s TECHSPO demonstration booth.

One of those industry partners is 3M, a lead sponsor of NLSC and host of a booth that showcases how 3M is shaping the future of work today with interactive demonstrations. For the past 40 years, the company has donated mentorship, personal protective equipment, funds and other resources to SkillsUSA’s efforts. More than that, as a global innovation leader, 3M is a model of how innovative and impactful skilled trade work is.

“We’re concerned when we hear folks describe the trades as dark, dirty and dingy,” Michael Stroik, 3M’s Vice President of Community Impact, said. “Our 3M State of Science Insights survey shows that people respect the work of manufacturing but don’t necessarily see its connection to innovation. Making that connection is really important to us.”

The manufacturing workforce behind 3M has produced hundreds of game-changing products, touching everything from space exploration – 3M produced the material on the soles of the space boots that left the first footprints on the moon – to the N95 masks that kept front line workers safe during the covid-19 pandemic. None of 3M’s critical innovations would have been possible without skilled trade workers.

“We’re manufacturing for the future of a growing world and that can inspire students to think differently about careers in this space,” Stroik said.

Jana Kawasmi overlooks the crowd at the SkillsUSA National Leadership & Skills Conference opening ceremony.

Investment that inspires

Jana Kawasmi, 18, a Texas high school graduate, has climbed the ranks within SkillsUSA leadership development programs to serve as a one of nine elected high school national officers who act as ambassadors for SkillsUSA initiatives to business and industry partners, government officials, students and educators. She plans to pursue a skilled trade-facing engineering path, but that wasn’t always her intention. She was initially set on being a doctor because she wanted to help people.

Kawasmi credits SkillsUSA for sparking her interest in engineering. “It wasn’t until I started competing in SkillsUSA competitions that I realized I love team engineering,” she said. “I love critical thinking. I love working with people. I love developing new solutions and there are so many problems in the world that need fixing.” Kawasmi realized she could help people by building bridges — literally — and shifted her focus toward engineering. She transitioned to a STEM-specific high school where “SkillsUSA is kind of our football.”

3M’s TECHSPO booth at the SkillsUSA National Leadership & Skills Conference.

That is the exact perception change SkillsUSA targets. The organization, with sponsorship from 3M, hosts an annual National Signing Day event, where students are celebrated for committing to a skilled trade field as a first career choice, much like the fanfare given to high school athletes who sign letters of intent when joining collegiate sports. Students sign job offers and commitments to internships and apprenticeships surrounded by balloons, local news coverage, flashing cameras and cheering crowds.

Kawasmi pinpoints pride as a key element in building the appeal of trade work. Some people feel shame in not pursuing a college degree, when, she said, they should feel proud. “What matters is: Are you using your skills, your energy to help society grow? Are you connecting with other people to help them make the world a better place?”

“You’re still getting certified,” Kawasmi added. “You’re still getting a diploma.”

A group celebrating students committing to careers in the culinary arts at a SkillsUSA National Signing Day event.

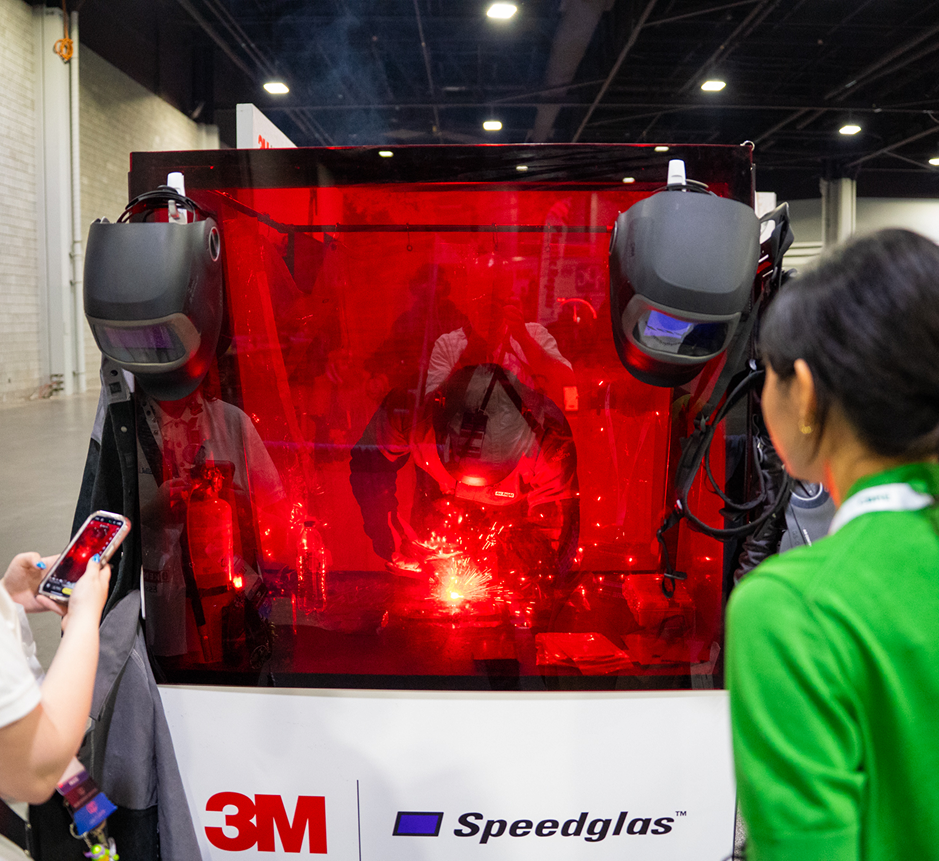

A SkillsUSA student inspects a 3M Speedglas Welding Helmet with 3M employee Michael Hallock.

The shift at work

A core pillar of SkillsUSA’s work is showing how a skilled trade career benefits the individual — not just the nation. The group celebrates that students with exposure to career and technical education programs are more likely to graduate high school and, eight years post-graduation, they’re more likely to be employed full-time and have higher annual earnings.3 Stroik said this is one of many reasons 3M supports SkillsUSA. “It’s about that economic mobility on an individual basis, enabling people to grow their economic opportunities.”

Of course, 3M’s success as a business is also deeply connected to the quality of the available talent pool. “We recognize very clearly that this is a long-term game for us,” Stroik said.

The company is investing heavily to win that long-term game. Last year alone, 3M invested over $28 million in education and training programs, in-kind donations to SkillsUSA and other organizations and thousands of hours of employee volunteer time. The company also fosters deep relationships between its manufacturing plants and surrounding schools by designing curriculums, securing classroom equipment, providing subject matter expertise in the classroom, hosting plant tours and offering scholarships.

Two conference attendees watch a welder in a helmet made with 3M Speedglas, a material crafted for welding safety.

Building momentum

Stroik, Kawasmi and Travis all acknowledge more needs to be done to attract young talent to these trades. “3M and industry itself can’t solve this alone. SkillsUSA can’t solve it alone. Education and government, we can’t solve it alone,” Travis said, recognizing the cross-sector work required to tackle the skills gap.

The good news is that the work is happening and it’s succeeding, according to Stroik. “The education sector, the private sector, policymakers on both sides of the aisle are saying, ‘Hey, trade issues, training, workforce development and engagement are important.’ That builds a momentum.”

That momentum was palpable on the convention floor at NLSC, as young skilled trade hopefuls exchanged ideas, met mentors and cheered each other on in competitions. As Travis put it, “I don’t know how you can leave our National Leadership & Skills Conference without feeling that our future workforce is moving in the right direction.”

A competitor connects pipes and fittings in the SkillsUSA Plumbing Championship. Photo courtesy of SkillsUSA.

Learn more about how 3M is investing in tomorrow’s workforce, today.

Sources

1Creating pathways for tomorrow’s workforce today, Deloitte and The Manufacturing Institute Manufacturing Talent study, accessed June 2025

2Labor Force Statistics from the Current Population Survey, Bureau of Labor Statistics, accessed June 2025

3CTE Works, Association for Career and Technical Education, accessed June 2025