FOR MORE

SUSTAINABLE FLIGHT

An aerospace and defense company develops the technologies of tomorrow

Sustainability is a central objective for the aviation industry. Here’s how one of the world’s largest aerospace and defense companies is helping pave the way.

The aviation industry has a collective goal: Reduce carbon emissions to net-zero by 2050. It’s highly ambitious, especially considering the pressure to meet travel demand by putting significantly more planes in the air. “Commercial aviation has roughly doubled every 20 years, and we anticipate that growth to continue,” said Juan de Bedout, chief technology officer at RTX, one of the world’s largest aerospace and defense companies.

The challenge of emissions reduction in the face of growth can be more than counterbalanced by the industry’s long history of collaboration, according to Haldane Dodd, executive director of the Air Transport Action Group (ATAG), a global coalition focused on sustainability efforts within the aviation industry. “We have 120,000 flights that take place every day across the world,” he explained. “From the engineers to the airlines to manufacturers to air traffic to government regulations, it’s a global dance of collaboration to even get one flight off the ground.”

This worldwide, cross-discipline teamwork is why Dodd is confident the industry will reach its sustainability goals. “We’re not unique in facing climate challenges, but we are unique in the fact the aviation industry is working together to make change happen as a whole sector,” he said.

ATAG is leading the commercial transport industry’s charge into a more sustainable era in aviation, and RTX, which employs more than 185,000 people worldwide, is using its expertise to help. In 2023, the company’s business units, which include engine maker Pratt & Whitney and aerospace manufacturer and supplier Collins Aerospace, invested over $7 billion in company- and customer-funded research and development, which included projects to advance sustainable aviation such as:

- Developing more fuel-efficient engines

- Advancing hybrid-electric propulsion

- Ensuring compatibility with 100 percent sustainable aviation fuels (SAFs)

- Making aircraft systems and parts lighter and more energy-efficient

- Optimizing air traffic management

“We’re not unique in facing climate challenges, but we are unique in the fact the aviation industry is working together to make change happen as a whole sector.”

HALDANE DODD, Air Transport Action Group

De Bedout shares that RTX is focused on building a sustainable way forward for the company and the industry by challenging its community of 60,000 engineers to be creative, reimagining what is possible in commercial aviation and driving differentiating innovation into all offerings.

Action relies on cooperation

Sustainability and efficiency have long been ingrained in the culture of RTX. Those efforts are now directed toward the industry’s net-zero emissions goal, which has facilitated investments and collaborations not only across business units but with governments, airlines and other companies.

“Collaboration is essential to our sustainability strategy,” said Phill Godfrey, chief sustainability officer for Collins. “Working across the business units within RTX is such a powerful way to unlock the breadth and depth of our company’s capabilities. In this way, we can direct resources to where they will have the biggest impact and we can identify system-level solutions that maximize our sustainability efforts.”

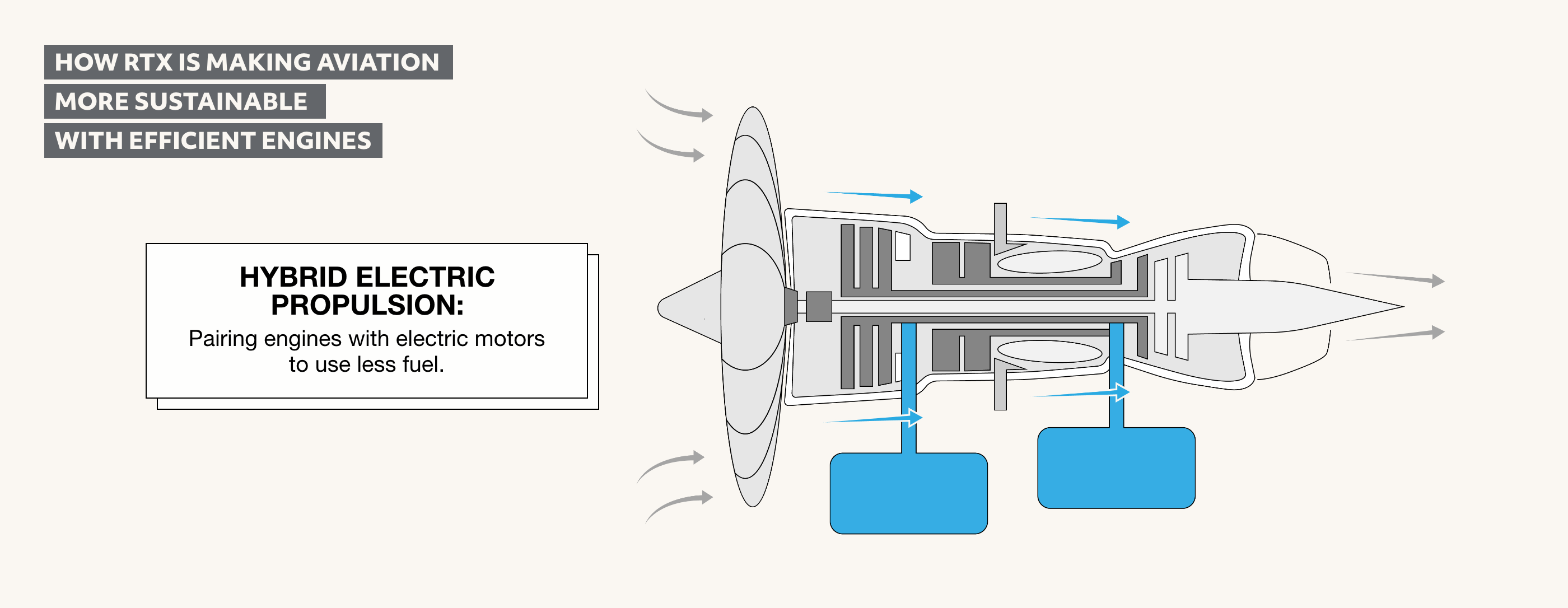

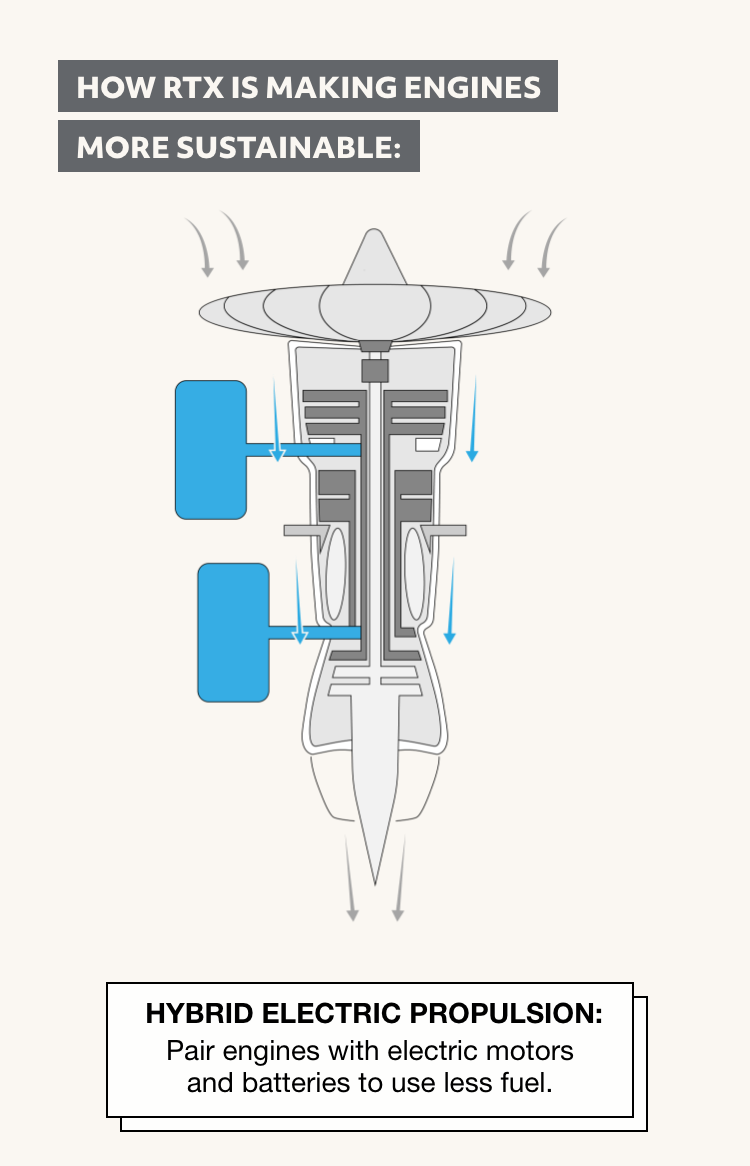

One such example: hybrid-electric propulsion. By combining thermal engines from Pratt & Whitney with electric motors from Collins, RTX is developing new hybrid-electric architectures designed to help significantly improve fuel efficiency and reduce carbon emissions for future aircraft. With support from the RTX Technology Research Center, the company is working on multiple hybrid-electric demonstrator programs including STEP-Tech, the RTX Hybrid-Electric Flight Demonstrator and the Clean Aviation SWITCH project. These demonstrators cover a breadth of different segments so that, ultimately, RTX will be able to offer hybrid-electric systems to a range of future aircraft with varying power needs — from urban air mobility to large commercial.

Collaboration extends outward, too. RTX is working with the International Aerospace Environmental Group (IAEG) to develop voluntary standards for the aviation industry. “This will create transparency and a more sustainable supply chain,” said Godfrey.

Other examples of collaboration within the sustainability space are RTX’s projects with Clean Aviation, the European Union’s sustainable aviation research and innovation program. “We’re currently working on several Clean Aviation projects,” Godfrey said. “Together with airframers, engine makers, suppliers and universities, we’re developing disruptive technologies to enable more sustainable aviation.”

“Working across the business units within RTX is such a powerful way to unlock the breadth and depth of our company’s capabilities.”

PHILL GODFREY, Collins Aerospace, an RTX business

The future of fuel

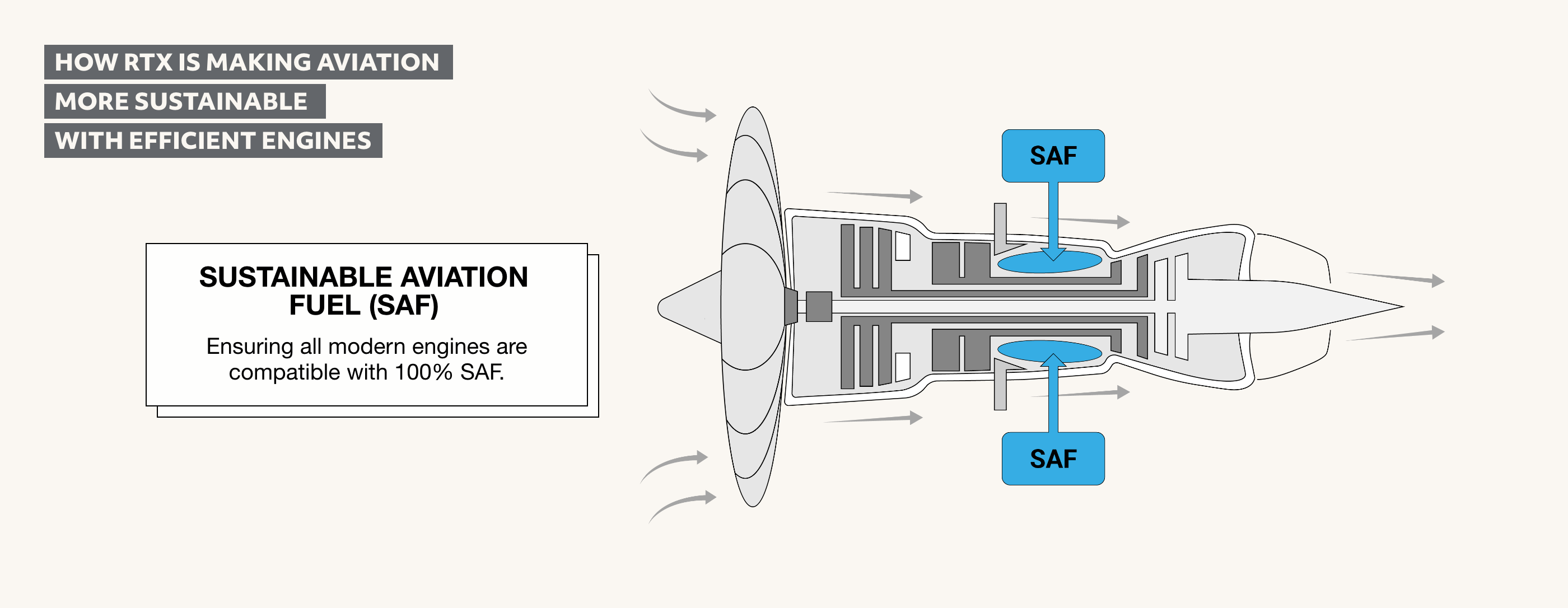

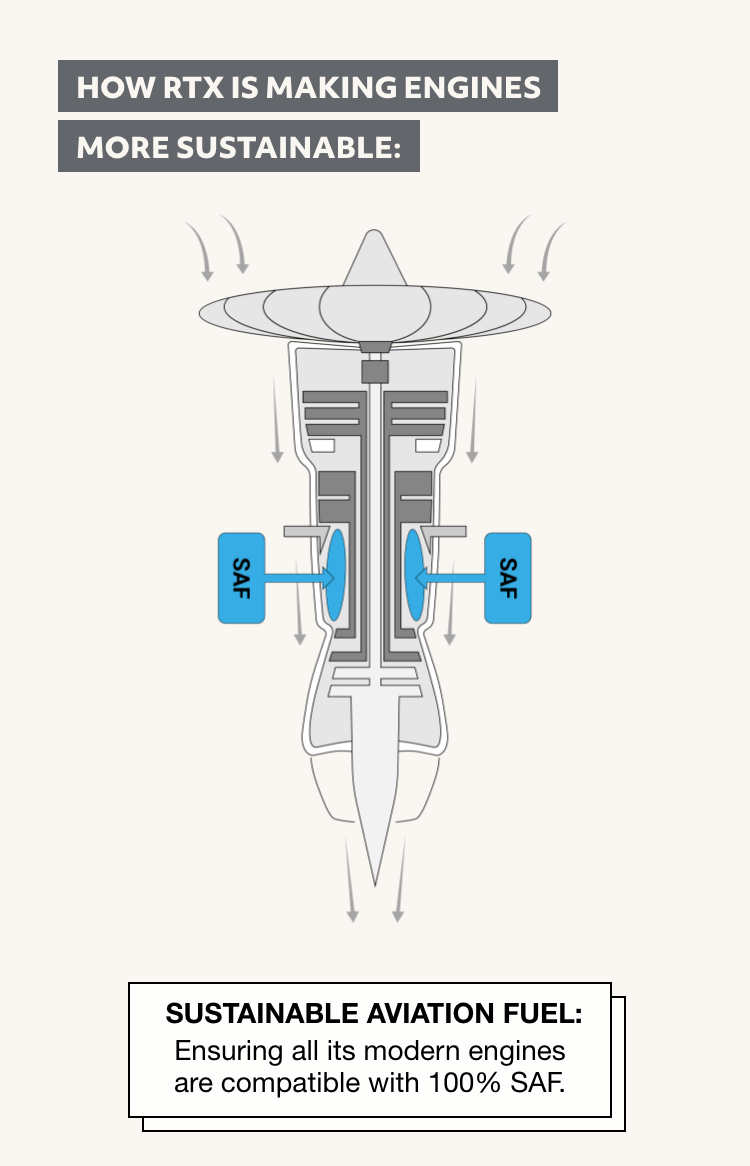

“As a ‘ready now’ technology, sustainable aviation fuels are the most crucial lever for reaching a more sustainable aviation industry,” said Graham Webb, chief sustainability officer of Pratt & Whitney.

Today, SAFs are primarily produced from feedstocks that absorb CO2 emissions from the atmosphere during their growth or creation and thereby enable a net reduction in emissions compared to fossil fuels. SAFs are scarce today because they are expensive to produce and the supply of feedstocks is limited, but RTX is supporting various public and private initiatives to increase demand and availability of SAF.

Pratt & Whitney has been active in SAF development for more than a decade and has ensured that all its modern engines are capable of operating with SAF blends of up to 50 percent with conventional Jet A and A-1 fuel. The company is also preparing its products for future fuel specifications that enable 100 percent SAF. This effort includes a comprehensive engine testing program and collaboration with industry associations such as ASTM International, the Commercial Aviation Alternative Fuels Initiative (CAAFI) and the IAEG.

RTX is also innovating advanced hydrogen-fueled propulsion technology which would use hydrogen produced from renewable energy sources, such as wind or solar power. For example, the company has partnered with the Department of Energy on developing the Hydrogen Steam Injected Intercooled Turbine Engine (HySIITE). This project aims to use liquid hydrogen combustion and water vapor recovery to achieve zero in-flight carbon dioxide emissions and a reduction in nitrogen-oxide emissions of up to 80 percent. “The concept is a game changer for when cryogenic hydrogen fuels ultimately become available,” Webb said.

Enhancing the engine

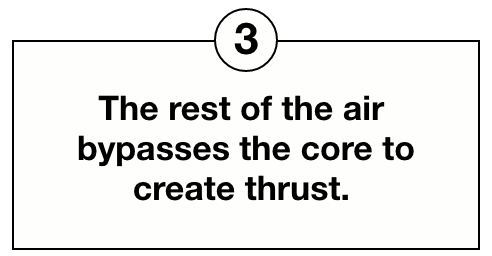

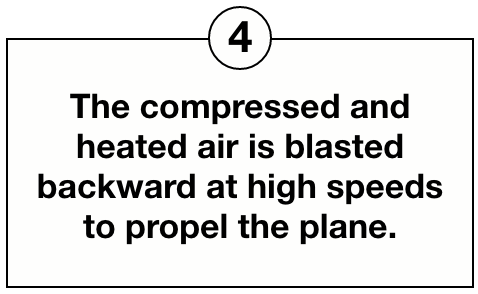

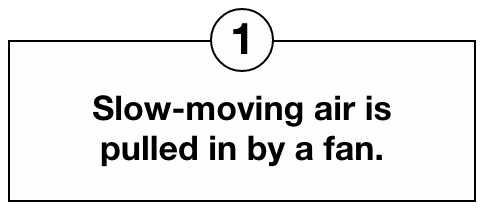

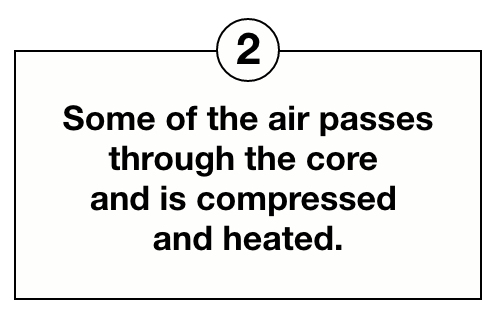

Since the dawn of aviation, propulsion providers have continuously driven improvements in engine efficiency to deliver better performance for customers, and that core mission continues today. According to de Bedout, enhancing engine efficiency — in the near-term and future — is one of the most important paths to net-zero CO2 emissions in the aviation industry.

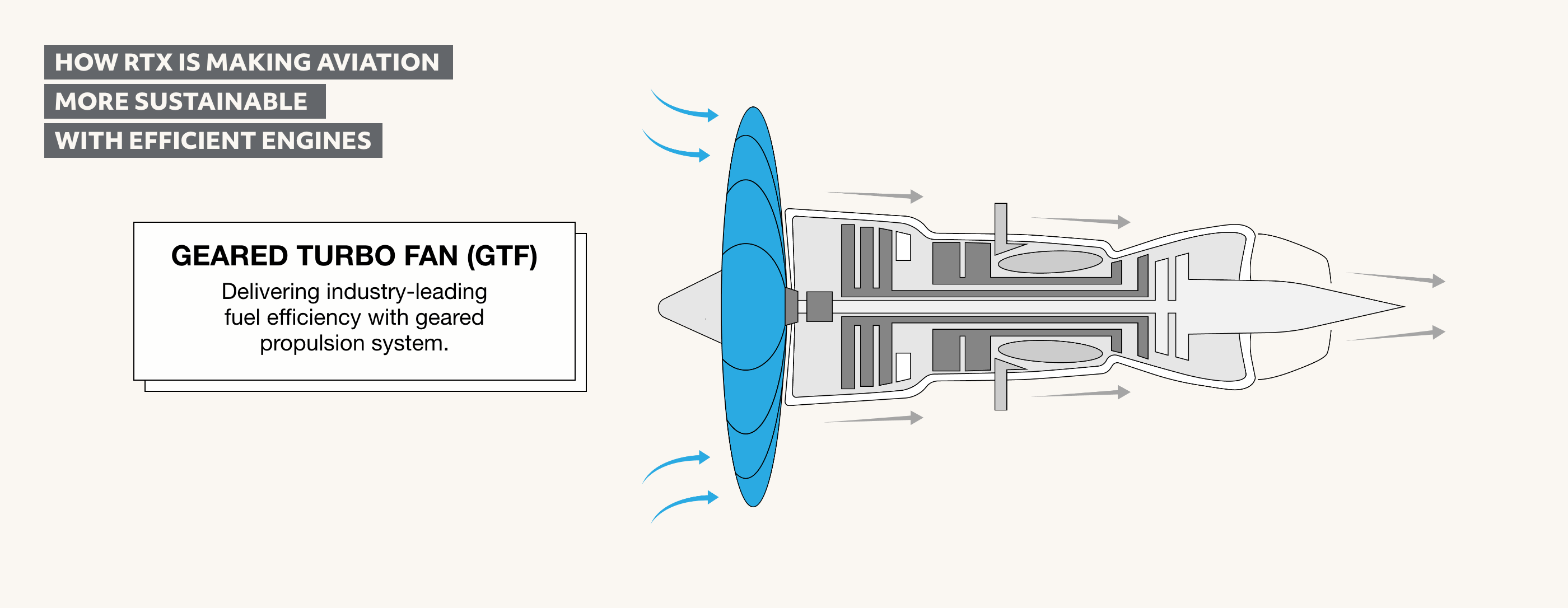

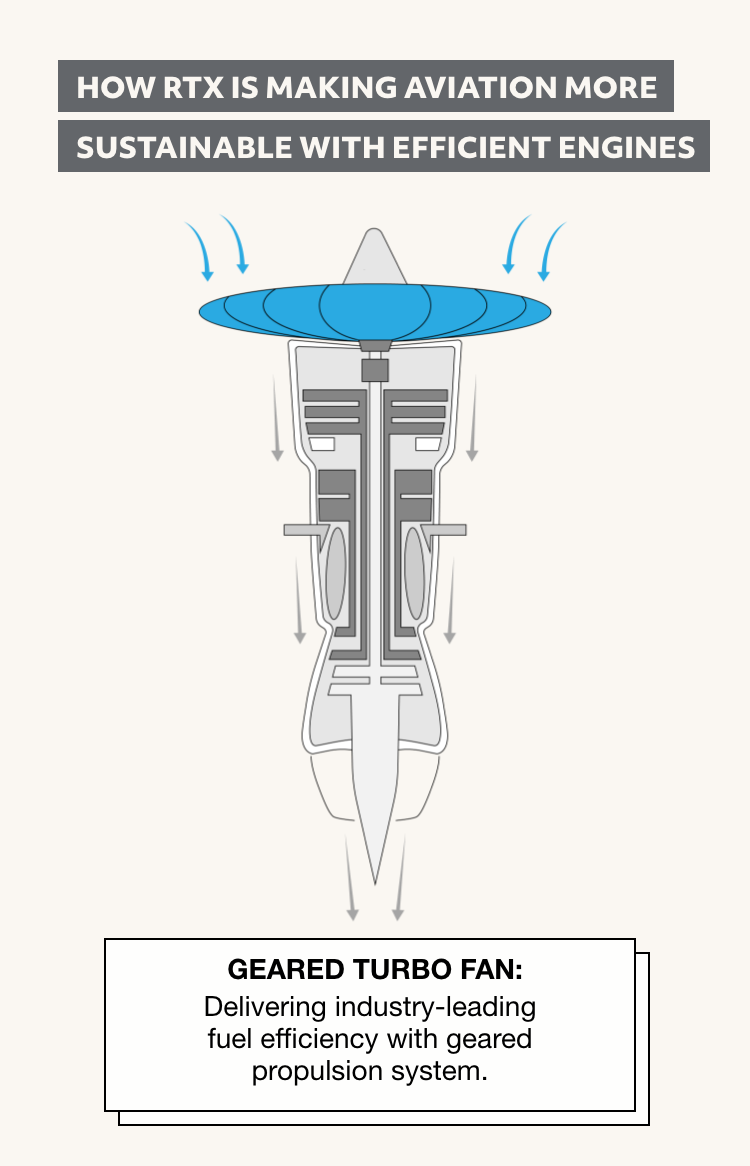

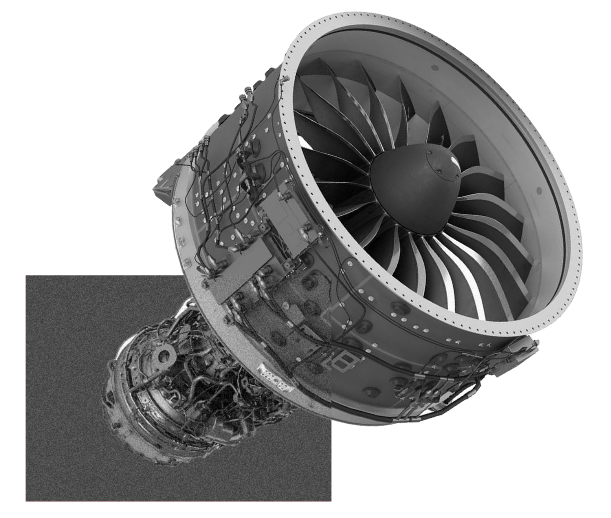

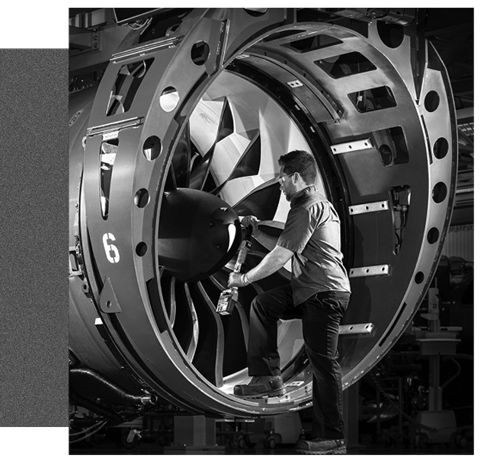

The Pratt & Whitney’s GTF™ engine is one example of how sustainability solutions from RTX have revolutionized commercial aviation. Unlike traditional engines, the GTF uses a gearbox to allow the engine’s low pressure turbine and fan to spin at different speeds to optimize aerodynamic efficiency, resulting in a more fuel-efficient machine that can reduce CO2 emissions by up to 20 percent compared to previous generation aircraft. Since its entry into service in 2016, GTF engines have helped airlines worldwide save more than 1.7 billion gallons of fuel and avoid 17 million metric tons of carbon emissions.

Other advancements under development include the use of high-temperature materials, and small cores with even larger-diameter fans that could optimize the GTF engine concept further. RTX is also developing a hybrid-electric GTF engine demonstrator as part of the SWITCH program, incorporating megawatt class electric motors developed by Collins.

Airframers are also looking at the design of aircraft to increase fuel efficiency. RTX has been selected by Boeing to provide GTF engines and aircraft systems for the NASA X-66 Sustainable Flight Demonstrator. Boeing will design and develop a new transonic truss-braced wing (TTBW) concept aircraft with thin, high aspect ratio wings supported by lifting struts which contribute to aerodynamic efficiency. When combined with expected advancements in propulsion systems, materials and systems architecture, a single-aisle airplane with a TTBW configuration could reduce fuel consumption and emissions up to 30 percent relative to today’s most efficient single-aisle airplanes, depending on the mission. “We are extremely proud and excited to have the opportunity to work with Boeing to power a new, more sustainable aircraft for the future,” said Webb.

“More and more people are connected through aviation. And we are putting the full weight of our company to supporting that connectivity in a way that safeguards the planet for future generations.”

JUAN DE BEDOUT, RTX

Analyzing data for sustainability

Reaching the net-zero goal will take more than best-in-class engine technology and advanced fuels. It’s going to involve the real-time choices that pilots, air traffic control and on-the-ground crews make every day. That’s why another key RTX initiative is increasing efficiency at every point during the gate-to-gate journey.

“We’re really harnessing data,” Godfrey said, adding that FlightAware, a division of Collins, uses predictive modeling to enhance operational efficiencies and help pilots determine the most efficient and sustainable routes. For example, contrails — the ice clouds formed when particles from jet exhaust mix with water vapor — trap heat in the atmosphere and contribute to global warming. Collins is working on leveraging flight and weather data sets to predict whether a flight path is likely to produce contrails, which will eventually allow for real-time flight adjustments that can avoid their formation while minimizing fuel burn for the mission. As part of the Federal Aviation Administration’s ASCENT program, Pratt & Whitney will measure non-CO2 emissions from a GTF engine combustor rig test stand using conventional Jet A and 100 percent SAF to help understand and reduce the environmental impact of those emissions, potentially including contrails.

“We’re changing the world. RTX is literally creating the future,” de Bedout said of the company’s abilities to meet the aviation industry’s environmental challenges. “More and more people are connected through aviation. And we are putting the full weight of our company to supporting that connectivity in a way that safeguards the planet for future generations.”

“We’re changing the world. RTX is literally creating the future.”

JUAN DE BEDOUT, RTX

RTX is leading the charge on

sustainability in the aviation industry.

SHARE THIS ARTICLE: